Do’s and Don’ts of Electrolytic Weld Cleaning

Weld cleaning | Wednesday, 11 December 2019

Electrolytic weld cleaning is a simple and straightforward post-weld cleaning and finishing process.

As with any industrial activity, there are procedures you can follow to further improve your production and avoid unwanted results.

Without further ado, here are the most essential do´s and don’ts of electrolytic weld cleaning – carefully selected by our industry experts.

Do’s of electrolytic weld cleaning

- Pick the right machine for the job

When it comes to electrolytic weld cleaning, using the right machine is already half the job done. Different machine models are suitable for different types of welds and contamination levels.

For example, cleaning heavily oxidized MIG welds requires more power. In such cases, satisfactory results can only be achieved by using our high-powered systems such as FURY 100 and FURY 200.

Smaller TIG jobs can be successfully done using any of our smaller machine models such as InoxPower. If you need something in between, and clean both TIG and thinner MIG welds, our most popular machine Cougartron ProPlus would be a perfect choice.

Wondering how to choose the right machine for your production? See our helpful guide here.

- Make sure you use the right working mode and power settings

Different weld cleaning tasks require the use of different working modes and power settings. This is primarily related to the type (light, dark, TIG, MIG) and thickness of the weld.

When it comes to choosing power settings based on material thickness, you can’t go wrong by following these simple rules:

- 30 Amps – up to 3-4mm (1/8″)

- 50 Amps – up to 8mm (5/16″)

- 50 – 200 Amps – equal and higher than 8mm (5/16″)

Note: The recommended settings for each machine are found in the user manuals.

For example, Cougartron FURY has an adjustable power output of 0-200 Amps ( 0-100Amps for the FURY 100 model) – suitable for a wide range of applications. It also offers three working modes based on the type of weld you are working with:

- Cleaning mode 1 – Light TIG welds

- Cleaning mode 2 – Dark TIG and light MIG welds

- Cleaning mode 3 – Dark MIG welds

Here is an overview of our machines and available power output levels:

- Pick the correct weld cleaning brush for the job

All of the above factors will also affect your brush selection considering that not all models are suitable for all applications.

For example, our FURY 200A weld cleaning brush is suitable for heavy-duty weld cleaning with FURY models operating at 80-200Amps.

Here are some basic rules to follow:

- Cougartron Powerbrush – 5-30 Amps

- Cougartron Superbrush – 30-80 Amps

- Cougartron FURY 200A brush – 80-200 Amps

- Inspect your equipment before every weld cleaning session

Damaged equipment (e.g. worn-out brushes, torn cables, damaged shrouds) can, at a minimum, cause unnecessary work delays and lead to serious breakdowns.

Therefore, a thorough inspection of the equipment before each session is a must.

If your weld cleaning brush is worn out, replace it with a new one. The same goes for cables, shrouds, wands, and all other accessories.

Read how to maintain and prolong the life of your weld cleaning brushes here.

In addition, you must make sure that you always have enough weld cleaning fluid at hand. Electrolytic fluids are one of the two key components of electrolytic weld cleaning. If you see too much smoke while cleaning or polishing, you need to wet the brush more.

Extra tip: Use our copper grease to prevent the brush from getting seized in the wand.

- Always use Cougartron accessories and consumables in combination with Cougartron machines

All Cougartron accessories and consumables are designed and developed to optimize the performance of Cougartron weld cleaners.

Therefore, you should always use them in combination with each other. Otherwise, it is very difficult to expect satisfactory results.

Additionally, any malfunctions caused by the use of incompatible equipment are not covered by our extended 2 year warranty.

- Utilize a wide range of available brush accessories to increase the effectiveness of your process

If you are struggling with effectively cleaning larger welds and hard-to-reach areas, you can always expect to find a suitable solution among our wide selection of brush accessories.

Our double and triple brush adaptors combined with appropriate shrouds and wands will significantly improve the speed of your weld cleaning.

Steel structures containing numerous cross-sections and corners are best treated with the help of our helpful angle adaptors. We also offer special Pipe brushes intended for cleaning the inside of pipes and tubes.

- Use recommended protective equipment (PPE)

Electrolytic weld cleaning often does not require the use of special protective equipment.

However, basic items such as gloves, goggles, and a proper ventilation are always recommended when it comes to industrial production.

To be completely sure, always check the available Safety Data Sheets (MSDS) files in our download area.

- Make sure to use enough weld cleaning fluid

Electrolytic fluids serve as agents during electrolytic weld cleaning.

Therefore, you need to make sure that both the brush and the work surface contain a sufficient amount of fluid at all times.

Otherwise, you risk a number of negative consequences:

- excessive smoke/evaporation

- burned work surface

- brush damage/wear out

- Move the brush in a circular motion during the weld cleaning process

Using your brush the right way has a big impact on the desired end result. We recommend using shorter circular brush strokes, especially if the heat-affected zone (HAZ) is wide.

This ensures that the entire area is properly cleaned – not just the weld bead area. The video below shows how this is carried out correctly:

- Keep your machine protected from (running) water

Our machines are equipped with a protective housing that is splash-proof but not water-resistant. If you expose your unit to a large amount of water, it is likely that electrical parts inside the machine will get irreversibly damaged or ruined.

- Inspect your work and treat the surface again if necessary

If, after the first pass, you are not completely satisfied with the result, feel free to make a few extra brush strokes.

This sometimes happens if the surface is too dirty, or not welded properly.

- Neutralize the surface after each weld cleaning session

Proper neutralization solves the problem with characteristic white stains and restores the pH neutrality of the surface. This, in the long run, further protects your metal parts against potential corrosion.

When applying the neutralizing fluid, use a generous amount and make sure you follow the steps listed in our quick guide below:

Click to read: How to neutralize stainless steel welds and surfaces properly

Don’ts of electrolytic weld cleaning

- Don’t ignore user manuals and utilize different working modes arbitrarily

Different working modes are created for a reason and allow you to perform different tasks in the most optimal way. Therefore, it is crucial that you follow the instructions and do not use any of the modules arbitrarily.

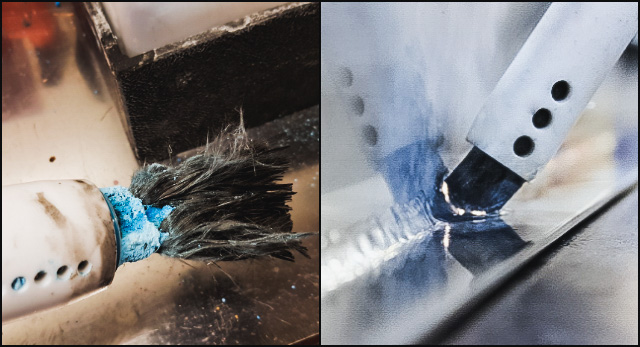

- Don’t use damaged and worn out brushes for weld cleaning

If your brushes have been stored in a damp place and have not been properly cleaned after their last use, it is likely that they are already sufficiently damaged to become completely unusable. In this situation, it is best to replace the damaged item with a brand new one. This reduces the risk of cross-contamination and eliminates a whole raft of potential performance issues.

- Don´t bend the weld cleaning brush during weld cleaning

Instead, use a shroud to properly secure the brush and control its length.

If you do not use the brush and the shroud in the right way, this can significantly slow down your process and reduce the quality of your results. It is also much easier for you to work with a secured brush.

The video below shows how this is done incorrectly – without securing the brush:

- Don’t replace neutralizing fluids with water

Neutralizing liquids should never be replaced with plain water. They contain chemical formulas that have been specifically developed to neutralize the surface (after the application of weld cleaning acids) and make it clean and acid-free.

- Don’t use a dirty cloth to wipe off the excess fluid

The safest way to prevent cross-contamination during both weld cleaning and neutralization is to use a clean cloth or a paper towel when wiping off the excess fluid from the surface.

- Don’t forget to clean and store your equipment after each session

The best way to make your equipment as durable and as possible is to clean it after each use. Also, make sure to store it in a dry place without the presence of moisture.

- Don’t leave the machine ON after you are done with weld cleaning

Turning off the machine after use extends its lifespan and reduces your power consumption.

Also, remember to pack the machine away after use. It is important to keep it safe from dirt and debris when it’s idle.

- Don’t use the machine close to other non-weld cleaning flammable items

It is a general practice to keep all electrical devices away from flammable materials. This also applies to machine units used for electrolytic weld cleaning.

- Don’t ignore the MSDS files

Cougartron weld cleaning fluids are phosphorus-based and much safer than the pickling paste.

However, if not handled properly, there is always a risk of mild injury and irritation. In these situations, it is very important to know what steps to take to maximize your safety and minimize the damage.

For this reason, we recommend that you study available Safety Data Sheets for the liquids that you use (available within our Download area). They contain vital information on the composition of the liquids and the preferred handling practices.

- Don’t work in a poorly-ventilated area unless you use the recommended PPE

Evaporations generated during the electrolytic process are safer than welding fumes since they consist mainly of steam (roughly 80% steam, 20% smoke).

However, no evaporation is 100% harmless, especially if it occurs indoors.

If not working outside, make sure you work in a well-ventilated area or use the recommended PPE stated in the safety data sheets found in our download area.

Click below to download a practical Do´s and Don’ts one page poster summary.

English

English  English (US)

English (US)  German

German  Danish

Danish  Swedish

Swedish  French

French  Polish

Polish  Spanish

Spanish