Electrochemical marking & Etching – All you need to know

Marking & Etching | Wednesday, 14 October 2020

Electrochemical marking and etching – easy and convenient way to mark/etch stainless steel and other types of metal surfaces

What is electrochemical marking and how does it work?

Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids.

But how does this process compare with other marking methods?

How permanent are the results of electrochemical marking and why is this important for industrial production and hobby projects?

Answers to these questions and other important information about the electrochemical process can be found below.

Metal Marking and Etching – Is there a difference?

Before comparing different marking methods and assessing their importance, we must first explain the difference between some of the terms that are often used simultaneously to describe this process.

Terms such as ‘marking‘ and ‘etching’ are often used interchangeably to describe two similar metal branding operations.

However, there is a slight but significant difference between the two processes. This should be taken into consideration when choosing the proper equipment for your application.

- Marking creates a dark imprint on the metal surface without changing its upper layer. Thus, the darkened color tone of the surface is the only change that occurs as a result of this process.

- Etching produces a small incision on the surface of the metal and removes some of the material. The resulting mark has a light/whitish appearance.

See more about the difference between electrochemical marking and etching HERE.

Why is the permanent marking of metal parts and surfaces important?

Metal parts and machines are marked and etched for traceability and enhanced branding. This includes logos, QR codes, serial numbers, dates and other information relevant to industrial production.

Part tracking and identification are also prescribed by law in a growing number of industries.

Metal marking is also widely applied in knife making, sculpting, and other forms of fine craftsmanship.

If you would like to know more about the importance of electrolytic marking in various industries and sectors, we recommend our detailed article below:

Marking/etching methods and techniques

There are several different marking and etching methods and techniques available to industry professionals. Here are the main ones:

- LASER MARKING AND ETCHING

This method includes the emission of focused light beams artificially amplified to provide desired results on the metal surface.

Laser marking and etching machines differ in terms of size and type – Fiber, Carbon-dioxide (CO2), and Ultraviolet (UV) are just some of the variations.

They all provide fast, clear, and consistent results on metal surfaces. However, you also have to be ready for a substantial capital investment due to the high price of most quality models.

- DOT PEEN(ING) is primarily an engraving process done through a specialized stylus which creates a dotted pattern/design on the surface of the metal.

The stylus is controlled pneumatically or electromechanically. Dot Peen method is mostly applied on thicker metal surfaces where contact with the stylus will not cause deformation.

The method will provide permanent marks but should not be used where clear and precise results are expected.

- INKJET MARKING

Inkjet marking is a printing process that creates semi-permanent marks on the metal surface.

Pressurized ink is applied to the surface through dedicated print nozzles that are controlled and positioned precisely to deliver proper marking results in terms of resolution and size.

Depending on their quality, Inkjet marking machines will provide fast and pleasing results. However, printed marks are prone to fading and are not as durable as those produced by other methods.

- ELECTROCHEMICAL MARKING AND ETCHING

Electrochemical marking and etching are done exclusively on conductive metal surfaces.

A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid.

Dark marking and white etching results are achieved by switching between Alternating (AC) and Direct (DC) electric current – and through the use of appropriate marking stencils.

Compared to other methods, electrolytic marking/etching is far more flexible and is mostly done with highly portable and affordable equipment.

Electrochemical marking and etching are especially effective on stainless steel surfaces.

Stainless steel is widely used in modern industry due to its anti-corrosion properties and attractive appearance. Machine parts, cutlery, and kitchen appliances are just some of the evident examples.

Electrolytic etching and marking will provide fast and clear results on stainless steel parts and finished products. No surface distortion occurs – even on very thin metal plates.

Electrochemical Marking / Etching Process

Etching / marking with electrochemical machines is extremely simple and consists of only a few short stages:

- Stencil/mask printing

- Surface preparation (quick cleaning)

- Fluid application and stencil positioning

- Actual marking/etching with the use of the electrode head

- Surface neutralization after marking/etching is done

How To Choose The Right Marking and Etching Equipment?

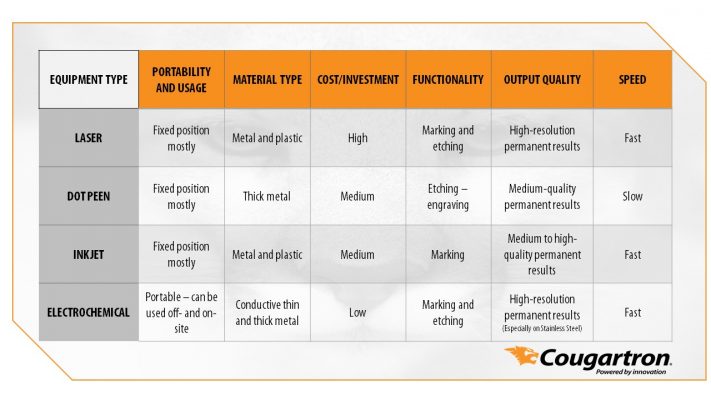

When choosing equipment for marking and etching, there are several important factors to be taken into account:

- Equipment portability and usage – Will you require a portable machine that can be moved around easily and used on-site?

- Material type – Do you need to mark/etch metal only?

- Cost – How much money are you ready to invest in the equipment?

- Functionality- Do you need to etch, mark or both?

- Quality- Are high-resolution mark and etch results desirable in your line of work?

- Speed – Is speed a relevant factor to your production?

Here is an overview of different marking and etching equipment types with the most prominent characteristics.

Electro marking and etching machines are ideal for workshops where extra workspace and increased flexibility are an absolute necessity.

Portable and lightweight – electrochemical systems can be easily moved around the workshop area and even used on-site where needed.

The process provides fast, clear, and high-resolution results on conductive metal surfaces – stainless steel especially.

Recommended Electrochemical Marking and Etching Equipment

Marking Machines

MK12 marking and etching machine

MK12 is a lightweight and portable electrochemical system designed for fast, safe, and non-destructive metal marking/etching.

The machine weighs only 5.47 lbs and comes packed in a practical carrying case – ideal for on-the-go work.

MK12 is great for permanent marking and etching of logos, model numbers, codes, and names on all of your metal parts and components.

Cougartron MK612 marking and etching machine

The MK612 is our new marking machine intended for marking larger metal surfaces without losing color consistency.

The machine delivers fast, uniform, and consistent results thanks to its innovative variable-voltage technology.

Cougartron Basic Etching set

Cougartron machines have created a name for themselves as fast and reliable systems for weld cleaning and passivation.

However – with the addition of a marking head and specialized consumables – our machines can be transformed into powerful marking and etching units.

See how this works in the video below:

NOTE: If you own a ProPlus machine that was purchased before December 2019, you will need to use a special ProPlus Etching Set for marking. All newer ProPlus units (sold after November 2019) are compatible with the Basic Etching Set.

All components of the Basic Etching Set are conveniently packed in a recognizable carrying case for on-the-go operations.

SEE THE CONTENTS OF THE BASIC MARKING/ETCHING SET | SEE OUR WELD CLEANERS HERE

Marking/Etching stencils and printers

Cougartron SP100 thermal printer with cutter

The Sp100 printer gives users the ability to efficiently print single-use stencils for marking and etching – with the help of advanced thermal transfer technology and Nicelabel software.

TTP-245C thermal printer w/ full cutter installed

This high-performance thermal printer will produce 4-inch-wide labels at a rate of 6 IPS (inches per second).

Ethernet and USB connectivity included.

PT-D600VP Brother Label Printer

PT-D600VP is a fast and reliable printer for 0.7” – 0.9” single-use custom stencils. Use the full-color display and user-friendly software to easily prepare logo and QR code stencils for your metal parts and components.

PT-H500 Brother Handheld Label Printer

Brother PT-H500 is a practical handheld printer designed for the production of labels and stencils for electrochemical marking and etching.

PT-800W Brother Label Printer

PT-800W produces clear 360dpi resolution stencils at an amazing speed of 2.36” per second. The printer is equipped with a convenient user-friendly keyword for more effective work.

USB and Wi-Fi connectivity are included so you can print stencils directly from your PC/laptop and smart devices.

Multi-use reusable stencils

Electrochemical marking/etching stencils are usually disposed of after a single use. This is because they contain information unique to the metal part they are used on – Serial number is just one of the examples.

However, if you need to mark hundreds of metal parts with a standardized design and information – Cougartron can supply durable stencils that can be used up to 2000 times.

The high-resolution stencils are produced according to your custom-design and project requirements.

Marking/etching fluids

Electrolyte fluids are essential for clear and high-resolution marking and etching results.

Cougartron has developed several electrolyte solutions for different types of metal surfaces. We can also create custom fluid formulas for your application.

- Cougartron CGT-S1 marking fluid for stainless steel

- Cougartron CGT-AL marking fluid for aluminum

- Cougartron CGT-MS marking fluid for mild steel

- Cougartron CGT-BR marking fluid for brass

- Cougartron CGT-CO marking fluid for copper & zinc

- Cougartron CGT-TI marking fluid for titanium

- Cougartron CGT-SA marking fluid for stainless steel and Etching on aluminum

- Cougartron CGT-NC marking fluid for nickel

CGT-N5 neutralizing fluid

Cougartron CGT-N5 removes all acid residues after marking/etching and restores the pH neutrality of the metal surface.

CGT-N5 is compatible with all our marking & etching fluids and can be used on various metal types.

Thanks to its potent formula, the liquid is very effective on brushed steel – it easily penetrates the pores on the surface and removes even the most persistent acid leftovers.

SEE MORE ABOUT OUR MARKING FLUIDS HERE

Overview

Metal marking and etching are two closely-related branding processes.

Marking produces a dark imprint on the metal surface while etching is used to remove some of the upper metal layer and expose a frosty white mark.

Both marking and etching are widely used in the modern industry for proper branding, identification, and traceability of metal parts and components.

Several marking and etching methods and techniques are being used by professionals today.

The main methods – laser, dot peen, inkjet, and electrochemical – all provide significant benefits for the user.

We have paid special attention to stainless steel – a material that is widely used in modern industry and construction due to its aesthetic and anti-corrosive properties.

The electrochemical method stands out as the most flexible. It also provides a great number of other benefits for marking and etching professionals:

- Portable and affordable equipment

- Impeccable results on thin and thick sheet metal

- Low Capital Investment

- Fast and easy process

- Clear and high-resolution results

- Excellent with both marking and etching

- Extraordinary results on stainless steel surfaces

- Ideal for smaller production areas and workshops

As is the case with all metalworking methods, the use of the right tools is crucial for the entire process.

Cougartron has developed a line of highly-effective marking & etching machines for flawless results on stainless steel and other metal surfaces.

Marking machines & sets

Loading products...

Please wait while the products load.

Marking & etching printers

Loading products...

Please wait while the products load.

English

English  English (US)

English (US)  German

German  Danish

Danish  Swedish

Swedish  French

French  Polish

Polish  Spanish

Spanish