Why should I use an Electrochemical Weld Cleaner on my Stainless Steel Welds?

What is electrochemical weld cleaning?

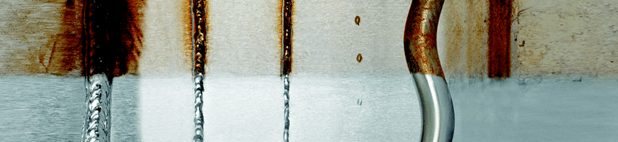

Electrochemical weld cleaning is a process by which post-weld impurities such as rust, heat tints, and discoloration are removed from metal surfaces under the effect of mild electrolytic fluids and a weak electrical current.

Read more about the benefits of electrochemical weld cleaning below or Book a Free Machine Demo now.

Why is Weld Cleaning Necessary After Stainless Steel Welding?

Welding destroys the protective layer on the surface and makes the steel susceptible to various types of contamination.

Weld cleaning removes impurities from the weld and the heat-affected zone. It also restores the protective layer of steel to permanently protect it from rust and corrosion.

Main Benefits of Electrochemical Weld Cleaning Compared to Other Methods

- Work flexibility – Portable and practical equipment for easy off- and on-site work

- Localized surface treatment – Choose which part of the surface you want to treat – no need to submerge entire metal parts in a liquid

- Low cost – Your initial investment and recurring costs are kept to a minimum

- Safety – The process involves a weak current and mild phosphorous-based liquids

- Surface (re)passivation – Restoration of the protective layer of steel

- Clean all types of contamination on all types of welds (TIG, MIG, SMAW, FCAW)

Weld cleaning vs Electropolishing

Although essentially similar, electrolytic weld cleaning and polishing differ significantly in how they affect the surface.

Specifically, weld cleaning removes surface contamination without altering the surface itself while polishing removes a microscopic layer of the surface.

Electrochemical Weld Cleaning Equipment

Electrochemical cleaning includes the use of specially designed and developed machine units, accessories, and consumables:

- Machine units with varying power outputs – We offer several different models to suit various production scenarios

- Brushes and accessories – Quality carbon brushes for successful results on different types of surfaces

- Fluids (acids) and accessories – Carefully developed formulas for different types of contamination

WANT TO KNOW MORE ABOUT ELECTROCHEMICAL WELD CLEANING?

You can read our detailed article here or contact us at any time using our email, phone number, or the practical form below:

Loading...

Please wait while the form loads.

English

English  English (US)

English (US)  German

German  Danish

Danish  Swedish

Swedish  French

French  Polish

Polish  Spanish

Spanish