The new model of our InoxFURY weld cleaner – Cougartron FURY 200 is now available!

Non classifié(e) | mardi, 09 février 2021

Introducing Cougartron FURY 200 Weld Cleaner

The Best Just Got Even Better – The New and Upgraded Model of Our InoxFURY Weld Cleaner Is Now Available

InoxFURY – the most powerful electrolytic weld cleaner – is celebrating its third birthday this year.

Its performance exceeded the expectations of many industry professionals who, after a long time, obtained a quick, effective and safe solution for treating large and heavily-contaminated surfaces after welding.

However, there is always room for innovation – especially with the constant helpful feedback that comes from our customers.

This is the reason for the development of the new InoxFURY model, which, in addition to numerous technical and cosmetic changes, also has a new name – Cougartron FURY200.

This helps to fit the machine into our planned machine-line up that will be increasing in the near future, as a result of our extensive and intensive R&D scheme.

The machine remains capable of heavy-duty cleaning and passivation of all types of stainless steel (and aluminium) welds and surfaces – with a maximum power output of 200 Amps.

Below you can find an overview of all the changes that characterize the new FURY200 model.

Cougartron FURY 200 – What’s new?

Updated Software & Electronics

The new version is equipped with a more advanced electronic system that provides additional stability and longevity to your machine.

This includes two advanced STMicroelectronics microprocessors found in each machine which, among other industries, are also widely used in the automotive sector.

The input voltage power, frequency, and alternating current and strictly monitored to ensure smooth, reliable, and consistent work every time.

Redesigned User Control Panel

Unlike the old model which featured a touch-button user panel, the new FURY200 model has rugged tactile buttons fitted below a waterproof membrane. The reason for this change is mechanical and practical in nature – the keys are much better protected against liquid deposits, and provide a greater tactile response, even when using gloves

The new setup enables up to a million switching operations, which brings a completely new dimension of longevity to the entire system.

The new FURY200’s buttons are used to control the work modes, which have been slightly changed compared to the old model. Here’s how:

Button #1 – Controls the weld cleaning functionality (first three clicks for different weld cleaning modes) and the marking functionality (4th click):

- MODE 1: for lighter TIG welds (20-200amps)

- MODE 2: cleaning darker TIG and lighter MIG welds (20-200amps)

- MODE 3: for dark and heavily-oxidized welds (20-200amps)

- MODE 4: marking (2-10amps) (Marking can be performed with an additional Cougartron Etching Set – sold separately)

Button #2 – Controls the polishing functionality (first two clicks for different polishing modes) and the etching functionality (3rd click):

- MODE 1: for polishing after weld cleaning on matte surfaces. (20-200amps)

- MODE 2: used to further polish welds on already polished parts. (20-200amps)

- MODE 3: etching (2-10amps) (Etching can be performed with an additional Cougartron Etching Set – sold separately)

In the video below, you can see the demonstration of all working modes

New Cables with Stronger Connection

The cables now run into the front of the machine unlike before when the sockets were placed on top. This change was made so that as little liquid as possible comes into contact with the sockets. This is also the biggest visual change when it comes to the new model.

Cables on all electronic devices are very prone to wear and tear, especially in industrial environments. To minimize this problem, we decided to make them thicker and stronger to withstand the very unfavorable working conditions faced by many welders. In addition, they are now also equipped with a dinse-style connector that prevents easy disconnection during work. All this, of course, contributes to a better and more stable current flow.

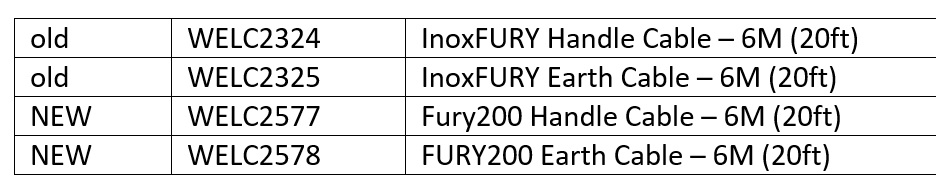

Here is the overview of the old and new part codes

More Robust Machine Housing

In order for all the new components to be properly connected into a functional whole, there have been significant changes to the housing itself, which is now much stronger and more durable. This guarantees greater stability during persistent work and frequent moving.

Stronger Wheels

The wheels make transferring the FURY200 from one work site to another less challenging and easier. We have now made them even more robust and durable so they are ready for different types of terrain and working conditions.

Made of solid molded plastic, the wheels are puncture-proof and acid-resistant. They will not be damaged easily when in contact with various liquids, tools, and scrap metal found in each workshop.

Additionally, the wheels are now completely black which contributes to the aesthetic appearance of the machine.

Improved Handle with Practical Cable Holders

Along with the wheels, the FURY200’s 2-part detachable handle is very useful when moving and transporting the machine. However, it now takes on an additional function – which is to hold and store the power and work cables when the machine is not in use or needs to be moved around the workshop/worksite. This allows you to transport the machine more easily without separating its cables and components.

Thanks to the addition of an integrated drip tray, the handle can now also be used to rest your brushes between cleaning sessions, which will greatly improve the flexibility of your work process.

New FURY 200 Brush accessories are now available

To complement all the changes, the new FURY 200 model is now also enriched with a large number of new weld cleaning brush accessories that provide you with extra flexibility and capabilities when using the system.

Thanks to the new accessories, it is possible to clean welds using 1-4 brushes simultaneously with your Cougartron FURY machine – depending on your workload and the type of weld. The new brush sets are equipped with an innovative heat-resistant twisting shroud system that allows precise control of the brush position, and its optimal protection.

All new weld cleaning brush sets are now available here.

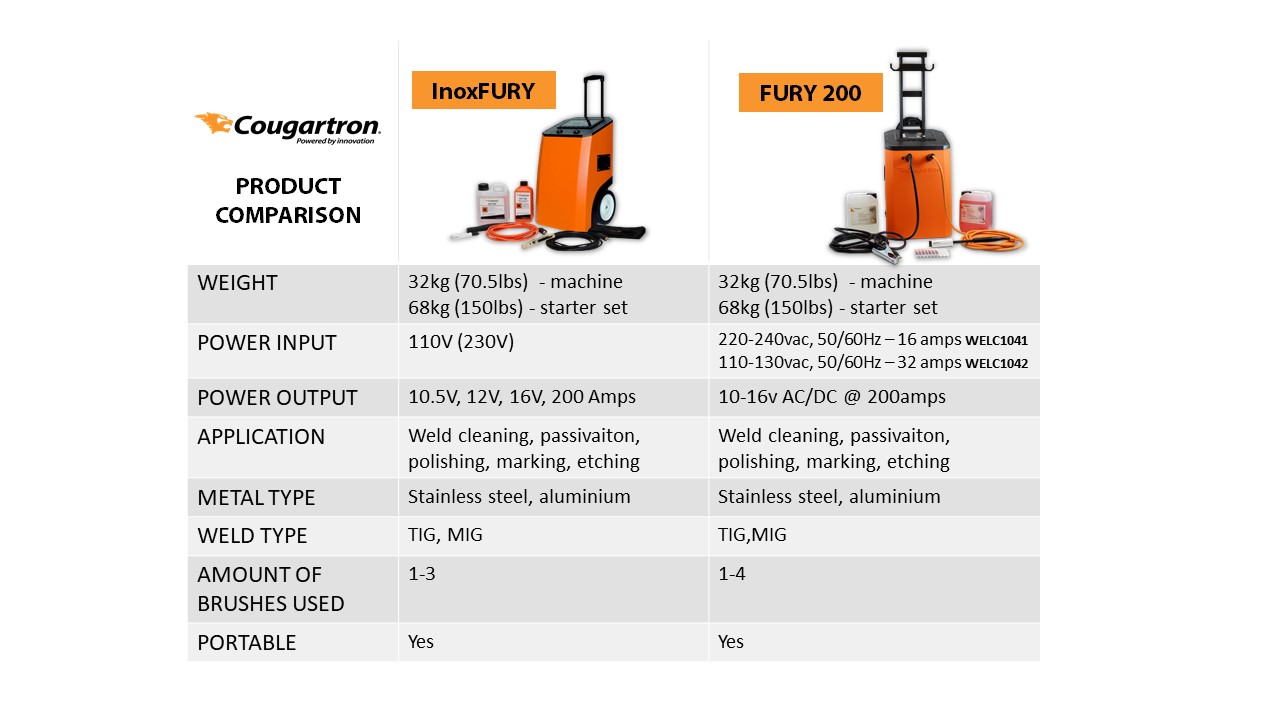

InoxFURY vs FURY 200

For your convenience, we have also prepared a detailed comparison of technical specifications below.

If you want to see the new FURY200 weld cleaner in action, click below to book a free demo with a member of the Cougartron sales team or a Cougartron dealer in your area.

Anglais

Anglais  Anglais (US)

Anglais (US)  Allemand

Allemand  Danois

Danois  Suédois

Suédois  Français

Français  Polonais

Polonais  Espagnol

Espagnol