Best Passivation Method for Stainless Steel

Weld cleaning | Stainless steel | Tuesday, 06 January 2015

What is passivation?

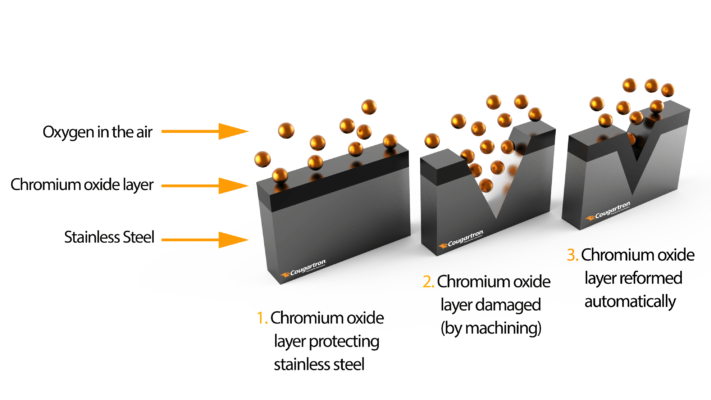

It’s a well-known fact that stainless steel is corrosion resistant. What is less known is that a passive, chromium-rich, oxide film that builds up naturally on the surface of the steel is responsible for the corrosion resistance. The formation of this passive layer is called passivation.

Passivation is a natural occurrence. However, it is possible to augment passivation by employing certain industrial techniques. These techniques involve oxidizing acid treatments. It can be said that an acid treatment is the best method of passivating steel.

Ambient Temperature and High-Temperature Corrosion Resistance

A simple oxide film or scale can be formed on the surface of the steel by applying heat. The same cannot be said for a passive layer. When heat is applied to the steel, the natural passive layer becomes thicker. In addition to changing volume, it changes color as it goes from heat-tint hues to a grey oxide scale. As a result of these visible oxide layers, the ambient temperature corrosion resistance of the steel is decreased.

Furnace parts are examples of stainless steel components that are tailor-made to function in really high temperatures. In order to stay protected from high-temperature oxidation, they are layered with these thicker, durable, oxide scale coatings.

On the other hand, in components that are made to work in ambient temperature environments, a thin transparent “passive layer” is enough to serve the purpose of corrosion resistance.

Requisites for Acid Passivation Treatment

Powerful oxidizing conditions can be used to boost the formation of the chromium-rich oxide passive layer on the surface of stainless steel. Nitric acid is the most suitable solvent for this oxidizing acid treatment. Its availability, convenience, and effectiveness make it a widely used solvent in industrial stainless steel passivation treatments. Other more weak oxidizing acids such as citric acid can also amplify passivation.

Steel components and fabrications that are derived from manufacturing mills and reputable stockholders are known to be fully passive. However, there are exceptions in each case. For instance, machined parts that have a complicated design and delicate structure may be in need of passivation treatments.

Why Stainless Steel Passivation is Needed

Owing to its intricate design, the surface of such a component may not be exposed to sufficient oxygen. As a result, the natural process of passivation is slowed down. If they are placed in a working environment that is suitable for fully passive steel components, then there’s a good chance that these complicated steel components will fall victim to corrosion.

Therefore, it’s absolutely essential to perform a passivation treatment on these components to remove the risk of corrosion.

Passivation Precautions

Certain precautions need to be taken prior to an acid passivation treatment.

These are:

- The steel surface should not have an oxide scale (it should be descaled)

- The steel surface should have metal surface layers uncovered in chromium from the formation of the oxide or heat tint layers erased by pickling.

- The steel surface has to be clean i.e. clear of organic contamination, machining lubricants, oils, and grease.

Cougartron Weld Cleaning

As mentioned before, cleaning is of great importance when it comes to stainless steel components. However, the process of cleaning or polishing can be tiresome and dreary. In certain cases, it could be potentially dangerous. In short, it’s a risky and time-consuming activity that many manufacturers are reluctant to perform. To erase the tediousness and dangerous elements in this task, one could use Cougartron weld cleaning systems.

Cougartron makes the entire cleaning process considerably faster, easier and safer. The secret to its effectiveness lies in its intelligent electronics, unique touch control user interface, self protection against surges and overheating, state of the art marking functionality and last but not the least, Cougartron’s brilliant service.

Read more about the Cougartron electrochemical weld cleaning method here.

See the full selection on Cougartron weld cleaning machines here.

Book a free demo with Cougartron!

Do you want to see Cougartron weld cleaning systems in action and learn how can Cougartron help you with cleaning and passivating your stainless steel parts?

Fill out the form below to book a free live or online machine demo.

Loading...

Please wait while the form loads.

Cougartron Popular Weld Cleaning Machines

Loading products...

Please wait while the products load.

English

English  English (US)

English (US)  German

German  Danish

Danish  Swedish

Swedish  French

French  Polish

Polish  Spanish

Spanish