How to choose the right Cougartron weld cleaner for your production?

Cougartron product news | Weld cleaning | Thursday, 24 January 2019

How to pick the right Cougartron weld cleaner?

Effective treatment and cleaning of metal surfaces after welding requires a great deal of effort.

Regardless of your skill level, using the right equipment plays a huge role in the entire process and can give you a tremendous advantage over the competition.

In addition to increasing the overall quality of your work, the right equipment will minimize your downtime and increase your efficiency. Needless to say, all this greatly contributes to your profitability.

On the other hand, using the wrong equipment increases your risk of losing money, time, and other vital resources.

Designing the production process and finding the equipment for its optimization is a painstaking task.

Therefore, we decided to provide a complete breakdown of our weld cleaner range to make your decision as easy as possible.

So, let’s begin.

Cougartron Weld Cleaner Range: The 3 Levels

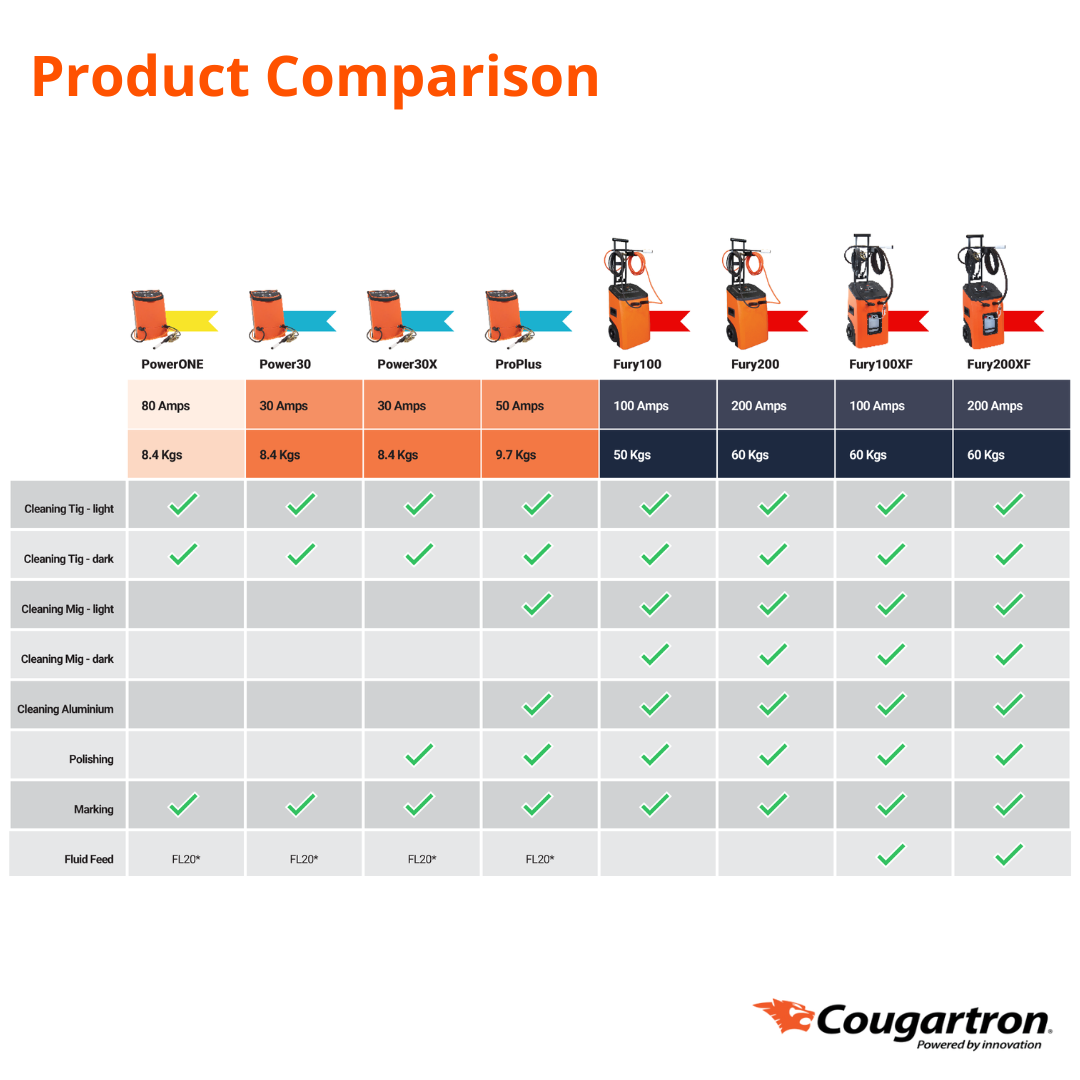

Our weld cleaner range is constantly expanding. We understand it can be difficult to keep track of all the options. That’s why we have divided our products into three categories, making it easier for you to understand the characteristics of the various models. The three categories are: Entry Level, Precision Range, and Heavy Duty Range.

Below is a detailed description of each category.

Entry Level range

Looking for a budget-friendly option? Our Entry Level range is the answer. The PowerOne machine, with its 80 amps of power output, is great for TIG and MIG welds and can also be used for marking (with the addition of the Basic Marking Set). If you require less power for more delicate projects, check out the Power30 from our Precision range.

Precision Range

The Precision range includes machines starting from 30 amps and building up to 50 amps. This range is perfect for on-site projects if you spend less than 5 hours per week cleaning welds. The machines are easy to carry and come in a handy carrying case.

Our Precision range features three unique machines:

- Power30: With 30 amps of power, this machine can easily clean TIG welds. It allows you to control the amp output and avoid workpiece overheating.

- Power30X: Similar to the Power30, but with an additional polishing capability.

- ProPlus: A versatile 3-in-1 machine for all your TIG and MIG projects. ProPlus is equipped with 50 amps, and you can use it for weld cleaning, polishing, and even marking (by adding the contents of the Basic Marking set).

All the machines in the Precision range are compatible with our FL20 Fluid Feed System, which automatically feeds the weld cleaning fluid to your brush, keeps it wet, and prevents it from burning out. This saves you both time and effort.

Heavy Duty Range

If you clean larger and heavily oxidized welds for more than 20 hours a week, this machine range is the perfect solution.

The heavy-duty category contains 4 powerful machines:

- Fury100: This 100-amp machine cleans TIG and MIG welds with ease. It can also be used for metal marking and surface polishing.

- Fury100XF: Similar to the Fury100 but with an integrated fluid feed system for faster, uninterrupted work.

- Fury200: This powerful weld cleaner is perfect for large projects, offering adjustable output power suitable for various tasks, both off-site and on-site.

- Fury200XF: Possesses the same characteristics as the Fury200, with the addition of an inbuilt fluid feed system and pump for maximum efficiency.

If you’re unsure which machine to choose, check out our machine selection guide below. Feel free to call us for a free demo, ask questions, and let us know your preferences. We’re here to help you find the perfect machine for your needs.

SEE OUR MACHINE SELECTION GUIDE HERE

What about different production scenarios? We’ve listed the most common ones below and added our machine recommendations so you have an even better overview.

Hobby Welding and DIY Projects

Art and craft projects involving welding and other types of metal fabrication share a large number of challenges and similarities with industrial production.

If the metal surface is damaged through cutting and welding, it quickly becomes highly susceptible to atmospheric elements and degradation.

Therefore, it has to be restored and protected against rust and other abnormalities. When it comes to stainless steel, maintaining its attractive appearance is another important factor to consider.

Sculpting, knife making, furniture building, and similar garage projects all require a thorough post-weld procedure as a measure of protection against corrosion and other impurities.

See how Cathal McCarthy – a visual artist from Ireland – uses Cougartron equipment to beautify his stainless steel sculptures after welding here.

Until recently, professional weld cleaning solutions were quite expensive and inaccessible to a wider population. For this reason, many hobbyists resorted (and still do) to dangerous chemicals (commercial and DIY) and messy manual methods such as grinding. We also encountered dangerous experimentation with car batteries to further enhance the effect of these chemicals.

Although these methods can be somewhat effective in removing impurities, they do not guarantee (re)passivation of the surface which is a prerequisite for effective and long-term protection against corrosion.

Considering all the nuances between different types of garage metalworking projects, we can recommend several weld cleaner models to suit your production habits.

- Cougartron PowerOne

This entry-level weld cleaner is ideal for hobby welders, offering effective weld cleaning and surface passivation at a fraction of the cost associated with some of the other models. It is also lightweight and highly portable, allowing you to use it beyond your workshop.

- Cougartron Power30

Power30 is slightly less powered but achieves amazing results on TIG welds, successfully removing oxidation and discoloration. This machine is best used during delicate projects where you need maximum control over the power output.

- Cougartron ProPlus

Is one of the most advanced solutions you can get for daily cleaning, passivation, metal marking, and polishing of all TIG (up to 10mm or 3/8 inch) welds and smaller MIG welds.

Low-scale Industrial Production

Metal processing within smaller production environments requires a lot of flexibility. Non-serial production is always challenging due to non-standardized output and a limited number of available resources.

When it comes to post-weld activities, we mostly consider simple and occasional weld cleaning and polishing tasks.

- Cougartron Power30X

The Power30X is an upgraded version of our Power30 weld cleaner, distinguished by the addition of polishing functionality. This machine features two weld cleaning modes: one for lighter TIG welds and another for darker ones. In addition to polishing and weld cleaning, you can use the machine for marking by equipping it with the contents of the Basic Marking set.

- Cougartron ProPlus:

Is recommended, if you need to clean larger TIG welds (over 3mm – 1/8inch thickness) or smaller MIG ( max 5mm or 1/4 inch) welds on a daily basis. ProPlus is a 50amp powered machine with weld cleaning, electropolishing and metal marking abilities. See a ProPlus demo video below:

High-volume Industrial Production

Frequent post-weld treatment of larger metal surfaces and structures requires strong equipment that can withstand intense routine and workload. The speed of the process is also an important factor as it directly affects your productivity and the bottom line.

An example of this type of production is the assembly of storage tanks and the construction of steel pipework.

Our Cougartron ProPlus traditionally offers outstanding results in this area. ProPlus is powerful (50amps) enough to clean different grades of stainless steel. It is both effective on TIG (up to 10mm or 3/8inch) and MIG (up to 5mm or 1/4inch) welds. ProPlus also provides the necessary versatility as it can be used for various types of tasks including weld cleaning, polishing, and metal marking.

In fact, until recently, it was the most powerful weld cleaning system in our range. However, we still had a long way to go before meeting all needs of high-volume industrial production. We needed a machine that would be able to clean all types of welds (TIG, MIG, MAG, Stick, and other) – with improved speed and efficiency.

The development of Cougartron FURY 200 was the right answer. As the most powerful weld cleaner on the market, it is suitable for the most demanding weld cleaning tasks. Cougartron FURY 200 can utilize three weld cleaning brushes at the same time making it extremely fast and effective when used on large and long welds and surfaces.

- Cougartron FURY 200 will surely provide an extra boost of efficiency for your production if you struggle to achieve fast and consistent results when working with thicker and larger metal surfaces. See below for a video comparison of our machine models cleaning 3mm MIG weld (InoxFURY is the original FURY200 model).

If your job involves only occasional treatment of heavily oxidized welds and surfaces, buying a 200 amp machine may not seem like the best investment.

This is where our new addition to the FURY line – the Cougartron FURY 100 – comes into play.

- Cougartron FURY 100

The advantages of the FURY 100 machine stand out in two scenarios:

– You do not need the full power (200 amps) of the FURY 200 model.

– You still need a high-powered machine for demanding oxide removal for long periods on both TIG and MIG welds.

FURY 100, therefore, imposes itself as the perfect intermediate solution between the FURY 200 (200amp) and ProPlus (50amp) machines.

- Cougartron FURY100XF and 200XF

These models are identical to their FURY100 and FURY200 predecessors in all aspects except one. The XF models feature an inbuilt fluid feed system responsible for automatically feeding fluid to the brush, eliminating the need for manual intervention. Therefore, if time is crucial in your production process, the FURY100XF and 200XF will certainly provide savings in this regard.

Machine Overview

Here is a practical overview of our Cougarton weld cleaning machines:

Book a Cougartron machine demo

If you are not sure which machine model would be best for your needs, or you have decided and want to see the weld cleaner in action, fill out the form below to schedule a free live or online machine demo with one of Cougartron representatives.

We have helped clients around the world find the right weld cleaning equipment and eliminate common problems associated with inadequate metal finishing methods.

Loading...

Please wait while the form loads.

Cougartron Entry-level Weld Cleaners

Loading products...

Please wait while the products load.

Cougartron Precision Weld Cleaners

Loading products...

Please wait while the products load.

Cougartron Heavy-duty Weld Cleaners

Loading products...

Please wait while the products load.

English

English  English (US)

English (US)  German

German  Danish

Danish  Swedish

Swedish  French

French  Polish

Polish  Spanish

Spanish