How Does Electropolishing Affect the Surface of Stainless Steel?

Weld cleaning | Electropolishing | Thursday, 31 May 2018

How Does Electropolishing Affect the Surface of Stainless Steel?

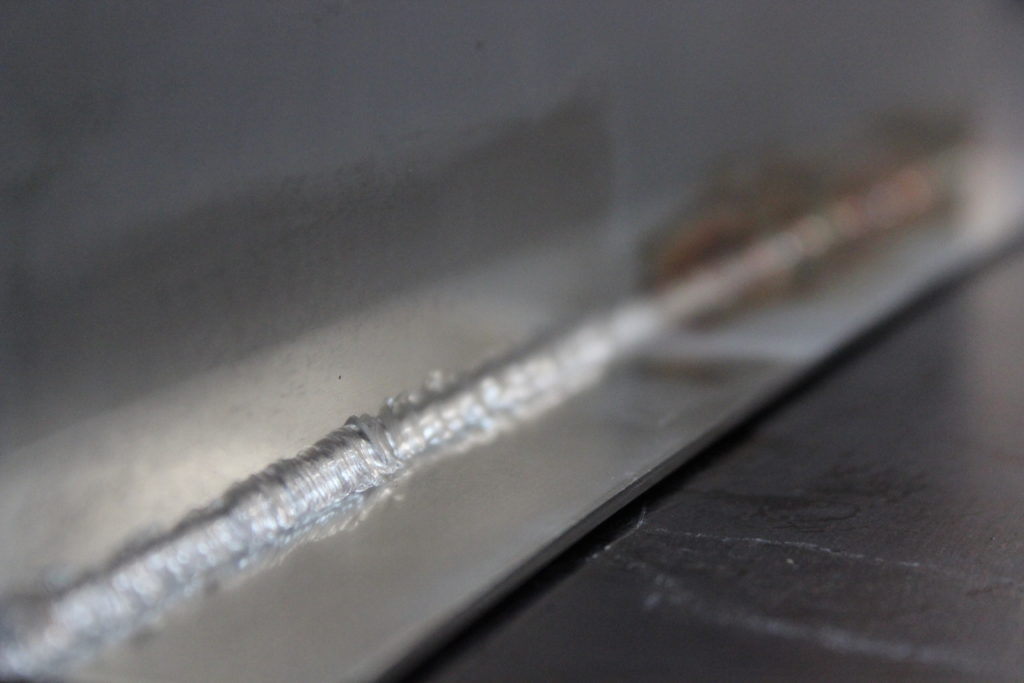

The high temperatures that welding requires can have a damaging effect on the surface of any stainless steel. Heat tint and scale are common by-products of the process, and harmful oxides of chromium can develop on the sides of the weld.

These oxides decrease the corrosion resistance of the steel significantly, and during their formation, chromium in the stainless steel is depleted. This oxidation, along with any areas of reduced chromium, needs to be removed.

Some fabricators turn to mechanical grinding with abrasives to clean up surfaces after welding, but this method is labor-intensive and can make the surface vulnerable to contamination. Another way of cleaning is through a chemical treatment called pickling, but this is also time-consuming and involves toxic chemicals.

5 Benefits of Electropolishing

Electropolishing eliminates imperfections and contaminants on stainless steel surfaces. Here are five reasons why it’s the best option:

- Corrosion resistance is enhanced

All the operations that go into stainless steel, both before and during welding, work together to damage its surface and degrade its properties. Machining, handling, welding, fabrication, and grinding can leave bits of iron and abrasive particles embedded in the steel’s surface.All of these surface contaminants hinder stainless steel’s natural ability to form a corrosion-resistant oxide layer. Electropolishing dissipates iron, inclusions, and embedded particles from the surface of the steel, making it better able to resist the onset of various types of corrosion.

- Microfinishes are improved

Improved microfinishes are more than just aesthetics. They can also:– Reduce friction

– Improve heat and light reflection

– Provide tighter seals

– Make sanitation easierThe electropolishing process has been shown to improve a surface finish reading by as much as 50%. And since electropolishing is not a surface coating, there is no need to worry about surface distortion or eventual peeling in the future.

- Contamination buildup on the surface is reduced

An improved microfinish means product adhesion and contamination are reduced, which means less cleaning is required. If cleaning is needed, these operations can be completed quickly and with less effort.Electropolishing simplifies the sterilization of surfaces that must be hygienic. Recent research also indicates that electropolished surfaces can help prevent the buildup of bacterial biofilms.

- Rough surfaces can be deburred

Mechanical processes such as grinding, vibrating, and tumbling can damage fragile or detailed components. Electropolishing is well-suited for deburring. It can remove burrs from these parts without the risk of distortion to the components. Another benefit: the hardness of the material does not factor into the time it takes or how much it costs. And, deburring and polishing the surface are done simultaneously. - A gleaming surface to admire

Appearance isn’t everything, but it certainly is the most conspicuous benefit of electropolishing. There are no directional polishing or buffing lines because no tools ever touch the surface. The electropolishing process results in a microscopically smooth surface that is both lustrous and striking.

How can you improve the surface of your welded components?

At Cougartron, we’ll set you up with a weld-cleaning machine that fits your specific needs and budget perfectly. Start getting outstanding results whether it’s cleaning, passivation, or electropolishing you’re looking to do.

Let us know what challenge you’re facing, and we’ll work with you to meet it.

Send us a message now.

Loading...

Please wait while the form loads.

English

English  English (US)

English (US)  German

German  Danish

Danish  Swedish

Swedish  French

French  Polish

Polish  Spanish

Spanish