Electrochemical Weld Cleaning – The Fastest and Safest Way to Clean Stainless Steel Welds

Weld cleaning | Wednesday, 14 October 2020

What is the fastest and safest method to clean stainless steel welds?

Electrochemical weld cleaning is a process by which post-weld impurities such as rust, heat tints, and discoloration are removed from metal surfaces under the effect of mild electrolytic fluids and a weak electrical current.

But what makes cleaning stainless steel after welding a necessity?

Is electrochemical weld cleaning effective and how effective is it actually?

How does this technique compare with other weld cleaning methods?

To learn more about these and other points related to electrochemical weld cleaning, please continue reading below.

Why is Weld Cleaning Stainless Steel Necessary?

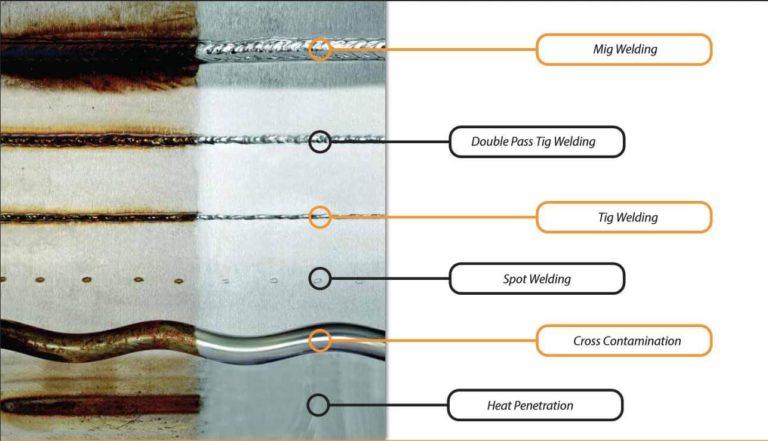

Weld cleaning is done to increase the corrosion resistance of metal surfaces after TIG, MIG, and other types of welding.

Metal surfaces and welds are quite susceptible to different types of degradation – Rust and cross-contamination are just some of the examples.

Problems such as discoloration and heat tints often occur after certain welding techniques are applied.

Both sets of problems can be eliminated through proper cleaning and finishing.

What Causes Corrosion?

The preparation of metal surfaces for welding leaves them exposed to different atmospheric elements like oxygen and humidity which creates perfect conditions for rusting.

This is why weld cleaning (and polishing) is crucial for the preservation of strength, shape, and other properties of steel structures. Increased durability and attractive appearance of metal surfaces are additional benefits of the cleaning process.

Types of Weld Cleaning

MECHANICAL WELD CLEANING

Mechanical weld cleaning includes the use of grinding machines and abrasives to remove the upper layer from the metal surface where rust and other imperfections are formed. This process is time-consuming and rarely achieves clean results with the necessary aesthetic value.

CHEMICAL WELD CLEANING

Pickling paste is the most commonly used chemical for weld cleaning. The process is fairly effective but is increasingly unpopular due to obvious shortcomings:

Health hazard – Pickling paste contains hydrofluoric, nitric, and sulfur acids. All of them are highly dangerous for the human body and can cause serious and long-term damage to the skin and internal organs.

Ease of use – Pickling paste can be used only by certified operators. In addition, the entire body has to be covered so no contact with the acid occurs. This adds a whole new level of complexity to your weld cleaning process.

Environmental impact – Immediate damage to the human organism is not the only negative side effect of using the pickling paste. Air pollution and waste materials pose a serious threat to the environment.

Read more about the dangers of the pickling paste here.

Is all pickling after welding harmful?

While we’ve highlighted the downsides of chemical pickling above, it’s essential to consider whether every form of pickling poses the same risks.

What if there is a safe alternative to chemical pickling?

Introducing Pickle ‘N’ Clean – our innovative paste featuring an effective and safe 2-in-1 pickling & passivation formula.

The best of all? It’s easy to apply in just four simple steps.

ELECTROCHEMICAL WELD CLEANING

Electrochemical weld cleaning is faster and more effective than the other two methods. Also, it does not pose a significant danger to human health.

This method is exceptionally effective with the removal of cross-contamination, rust, and other forms of impurity on metal surfaces – and always leads to a clean weld.

Electrolytic Weld Cleaning Process

The electrolytic cleaning process is extremely simple.

A mild electrolytic cleaning fluid is applied to the surface of the weld by using a conductive weld cleaning brush. Electric current (AC/DC) is employed so desired cleaning and passivation results are accomplished.

Here is a nice demonstration of the electrochemical weld cleaning and marking process:

Enhance Your Weld Cleaning Efficiency with Our Fluid Feed Systems

Dipping your weld cleaning brush into the fluid and applying it to the work surface is already a straightforward and fast process. But what if you could skip a few more steps, saving both time and effort?

Well, you’re in luck.

We have recently launched the FL20 – an innovative automatic fluid feed system for Cougartron weld cleaners. This practical device seamlessly attaches to the weld cleaner unit, automatically supplying the weld cleaning fluid to the brush.

With the FL20, you can eliminate the need for manual fluid application, making the entire process more efficient. It also allows you to move your weld cleaner and fluid container together, enjoying added flexibility in your daily work routine.

Sounds good?

Click here to learn more about the benefits of FL20

Manual electrochemical cleaning vs. electrolytic baths

The process described above refers to the manual application of electrolytic liquids to the workpiece using a carbon brush.

However, the electrochemical method also involves another approach, which is the use of special electrolytic baths (not to be confused with chemical pickling baths).

Instead of using a brush, the metal parts are immersed in electrolytic fluid where a chemical reaction occurs to remove rust and other contaminants from the surface.

Although very similar in principle, there are several significant differences between the two techniques that should definitely be considered:

- Work flexibility

Thanks to the easily portable equipment, manual electrochemical weld cleaning can be done on- and off-site. Contrary to this, electrolytic baths are constructed and kept within designated production areas.

- Surface treatment

When you submerge metal parts in electrolytic fluid, there is no choice but to affect the entire surface. Manual weld cleaning is most often done locally (weld area and the Heat-Affected Zone). This is a much more delicate and precise approach that gives greater control over how electrolytes affect the surface.

- Cost

When it comes to manual weld cleaning, the initial investment in equipment and the cost of consumables are kept to a minimum. With electrolytic baths, the associated costs (construction, maintenance, and operation) are much more pronounced.

Below we list several other distinguished benefits of manual electrochemical weld cleaning.

Benefits of Electrochemical Weld Cleaning

Here are the main benefits of weld cleaning with electrochemical machines:

Flexibility – Electrochemical cleaning systems are portable and you can easily use them on-site – you are not confined to a controlled area.

Safety – Electrolytic fluids only contain a mild phosphoric acid (also used in soft drinks) and can be used by both hobbyists and professionals. Protective equipment (gloves excluded) is unnecessary in most cases.

Process speed – Electrochemical weld cleaning is extremely fast. Good machines will clean and passivate the surface at the same time – no unnecessary hassle and repetitions.

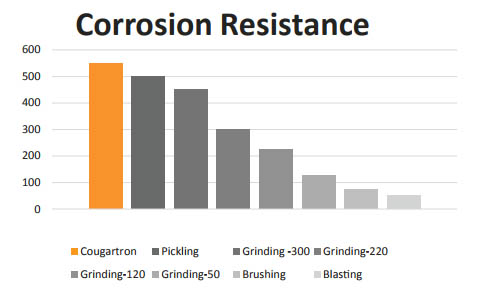

Optimal corrosion resistance – Our research suggests that the electrochemical process provides the best corrosion resistance compared to other cleaning methods.

Electrochemical weld cleaning is especially effective with stainless steel welds.

Why is this important? – Stainless steel is widely used in all industry branches due to its appearance, durability, maintainability, and high corrosion resistance.

Electrochemical Weld Cleaning vs Electropolishing

Although essentially similar, electrolytic weld cleaning and polishing differ significantly in how they affect the surface.

Specifically, weld cleaning removes surface contamination without altering the surface itself.

On the other hand, polishing removes a microscopic layer of the surface and, consequently, also removes surface contamination.

Naturally, the primary goal of electropolishing is to reduce surface roughness and improve the aesthetic appearance of steel.

If you want to know more about electropolishing, read our comprehensive article here.

Surface (re)Passivation and its Role in the Electrochemical Weld Cleaning Process

When compared to other steel alloys, stainless steel is unique in its ability to fight corrosion and preserve its structural integrity.

However, it is still far from being completely rust-resistant.

Here is why.

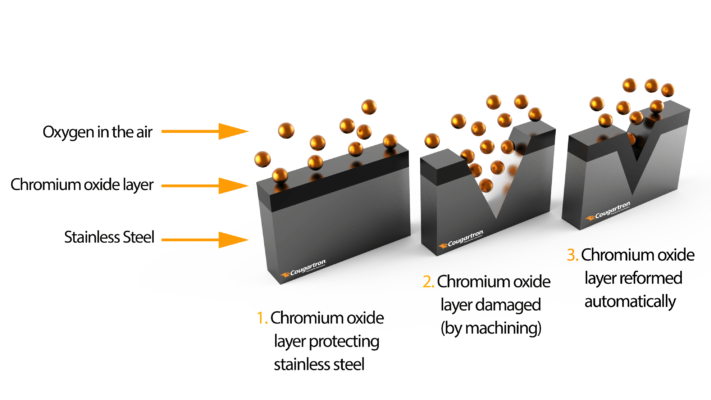

Thanks to its specific structural composition, stainless steel is equipped with a passive surface layer that stops oxygen particles and moisture from reaching its iron base.

This protective surface film is often heavily damaged during different types of fabrication (e.g. welding) and is then no longer capable of inhibiting corrosion.

After losing its passivity, stainless steel will naturally fall prey to rusting and – sooner or later – succumb to corrosion-induced decay.

But all is not lost.

The good news is that the passive protective layer can be completely rebuilt.

This process is called (re)passivation.

When utilizing the electrochemical method, surface passivation is conducted simultaneously with weld cleaning, which means that you will effectively finish both processes in one pass. You will be able to successfully remove different types of weld contamination (heat tints, discoloration) and protect the surface from future corrosion – all this at the same time.

It really is that simple.

This is actually one of the greatest advantages of the electrochemical method over other weld cleaning techniques.

Mechanical grinding and chemical pickling can provide decent results, but unlike electrochemical weld cleaning, these methods do not guarantee re-passivation, which is a huge disadvantage when it comes to stainless steel.

If you want to know more about the benefits of proper passivation, we recommend reading our detailed article on the subject:

Read more here: Passivation of stainless steel after welding.

Are Stainless Steel Welds and Surfaces Easy to Clean (and Passivate)?

The material is exceptionally resistant to corrosion. Under normal conditions, it will easily maintain its appearance and integrity – kitchen sinks are an excellent example.

However, the industrial environment is rather harsh, so it is extremely tough to avoid rust – particularly in the area of the weld.

The majority of common defects appearing on stainless steel welds – rust, discoloration, heat tints, weld and burn marks – can be easily and successfully removed through basic electrolytic treatment.

Electrolyte fluids can penetrate even the smallest cracks on the surface of metals and prevent further problems like pitting and corrosion build-up.

Electrochemical cleaning does not change the metal surface – it only returns it to its original (bright and shiny) condition.

Maintaining the attractive appearance of stainless steel is an important aspect of electrochemical weld cleaning.

So, are stainless steel welds easy to clean? – The answer is yes, but…

You need to make sure you use the right equipment (machines, accessories, and consumables) for the job.

Our Recommendations for Stainless Steel Weld Cleaning

Cougartron’s proprietary weld cleaning systems have been developed to answer the rising demand for fast and safe stainless steel cleaning solutions.

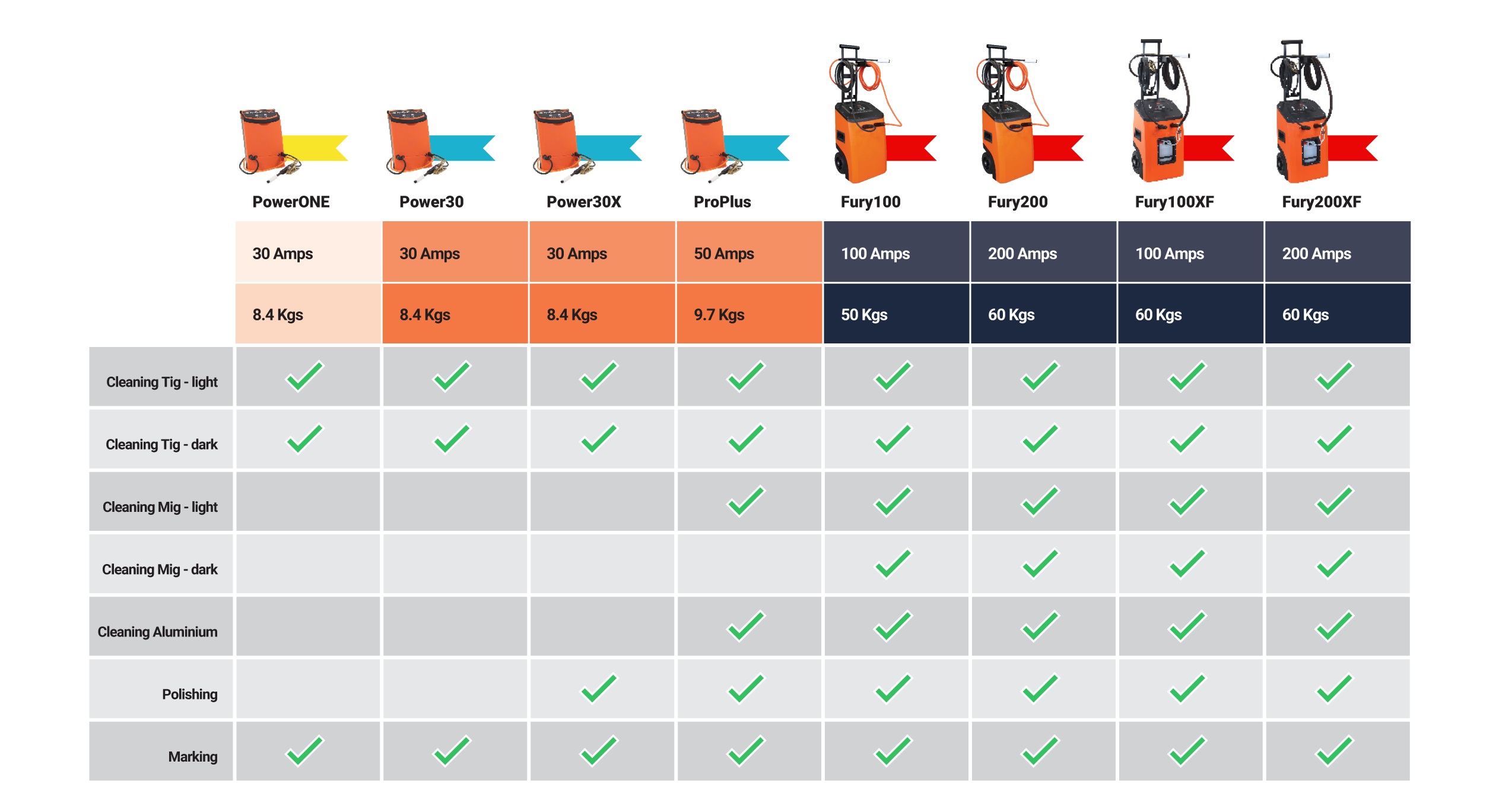

Over the years, our offering has expanded to include machines capable of delivering from 30 to 200 amps of output power, meeting a wide range of industrial applications.

They guarantee efficient cleaning and passivation of all types of welds with thorough removal of various levels of contamination.

For this reason, our weld cleaners are popular with all types of metalworking professionals – but also hobby welders.

Weld cleaning systems for stainless steel

When it comes to treating and preventing corrosion after metal fabrication, there is rarely a solution that is applicable in every situation.

The needs of hobbyists and professional welders differ in several ways, which makes choosing the right weld cleaning machine not a particularly easy task.

Among other factors, our machines differ in output amperage, available functionalities, performance, and size.

For example, if you only occasionally clean less-contaminated and slightly oxidized welds during DIY and hobby projects, then some of our 30Amp machines like Power30 or Power30X would be the right choice.

Our higher-powered machines such as the FURY100, FURY200, or FURY200XF are more suitable for serial and high-volume production in medium and large workshops.

No matter the project circumstance, we’ve got you covered.

Below you can find an overview of our machine models to determine in the fastest way which of them best suits your application.

Weld cleaning fluids – electrolytes

Thanks to their specially developed phosphorus-based formulas, electrolytic fluids (also commonly known as acids) successfully remove oxidation from the surface and prevent its re-formation.

Different types of liquids possess slightly different formulas, which determine their use and performance.

- Cougartron CGT-550 is the fluid of choice for most of our customers. It contains a formula that is suitable for both weld cleaning and electropolishing. The fluid can be used with all Cougartron machines and for all types of weld cleaning or polishing jobs – including the most demanding applications when your machine operates on high power settings.

- Cougartron CGT-350 sports a milder formula (and is thus transportable by air). Unlike CGT-550, the CGT-350 is intended solely for weld cleaning. The fluid works best with our 30 to 50amp machines, (InoxPower, Muscle or ProPlus) cleaning TIG welds. CGT-350 can also be used during higher-demanding cleaning jobs, although the cleaning speed will be reduced.

- Cougartron CGT-N5 – After using weld cleaning fluids, the surface must be properly neutralized, which is achieved using our new neutralizer formula – CGT-N5 Hy-performance neutralizer fluid. The neutralizer removes the acid residue from the surface and assures a clean finish on the treated area.

Are you struggling to store and transport fluid containers? Try our new CGT-650 electro passivation powder

Managing fluid containers in your workshop can be quite a challenge. They take up space, create clutter, and occasionally even pose legal issues during transportation. Moreover, they’re not always the most practical option for on-site weld cleaning.

That’s why our team developed the CGT-650 powder. It’s a real game-changer – Simply mix it with water to create the exact amount of weld cleaning fluid you need for your project.

The powder is conveniently packed in 70-gram boxes, which, when mixed with 1L of water, results in 1L of weld cleaning fluid.

But how effective is the mixture?

Rest assured, it’s just as effective as our trusted CGT-350 weld cleaning fluid, and you apply it in the same manner.

Weld cleaning brushes

The brushes are used to apply electrolytic fluid to the metal surface and conduct an electric current in order to make the weld cleaning process possible.

They are made of durable carbon-based material to foster the process and provide the necessary stability.

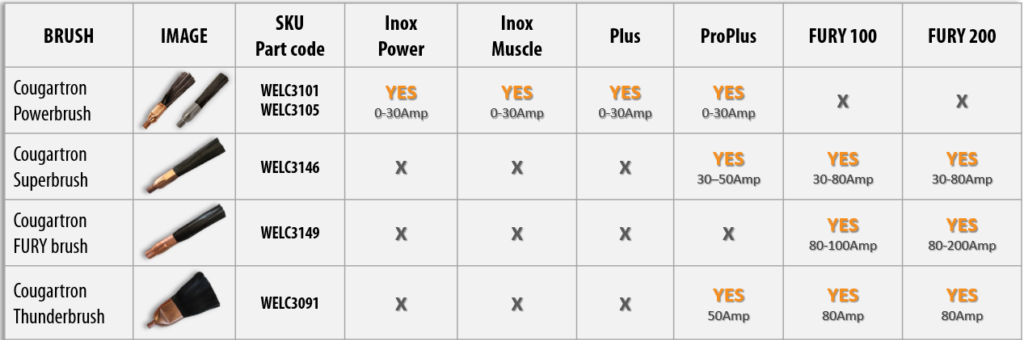

Since the brush is in constant contact with the surface during the weld cleaning process, it is very important that you use the right brush type in combination with proper power settings on your Cougartron weld cleaner.

Cougartron weld cleaning brushes are normally divided into two groups – Essential and specialized.

Essential brushes:

- Cougartron Powerbrush is a popular brush suitable for TIG weld cleaning jobs on less-oxidized welds and surfaces with InoxPower and InoxMuscle models at 5-30Amp cleaning output. The Powerbrush comes in two variants – with copper crimp and stainless steel crimp.

- Cougartron Superbrush is best used with an output of 30-80 amps on TIG and MIG welds with progressive oxidization. Superbrush is best compatible with ProPlus weld cleaner model

- Cougartron FURY 200A Brush is exclusively developed for our FURY models (FURY 100 and FURY 200). It is used to remove the most developed forms of contamination on all types of welds. The FURY brushes can be used with up to 200 amps of cleaning power. This is possible by using multiple brushes at the same time (2 – 4 brushes at once) thanks to our specialized brush accessories.

Specialized brushes:

- Cougartron Thunderbrush is a cleaning brush with a dense fiber structure to help cover a larger surface area. This brush is 4 times thicker than other Cougartron brushes, therefore is very useful when cleaning larger /thicker welds. The brush is best used at 30-50Amps.

To make it easy, we have created a brush overview and compatibility chart below:

Summary

Weld cleaning is a key post-welding process used to prevent corrosion on metal surfaces.

Three weld cleaning methods are distinguished:

- Mechanical (grinding with abrasives)

- Chemical (pickling paste treatment)

- Electrochemical (Cleaning with electrolytic fluids)

The mechanical process is fairly ineffective and time-consuming. Pickling is more effective but poses a dangerous threat to human health.

Electrochemical cleaning is a safe and fast alternative to these methods. It also provides better protection against corrosion and rust. The method is particularly effective when applied to stainless steel welds. Rust and other impurities are quickly removed and/or prevented.

Cougartron has developed a line of compact and strong weld cleaners designed to provide unrivaled cleaning performance and optimal results on stainless steel welds.

Book a free consultation

If you need help with your production or a specific weld cleaning project, please contact us for a free consultation at any time.

Our experts from Cougartron are always ready to help.

English

English  English (US)

English (US)  German

German  Danish

Danish  Swedish

Swedish  French

French  Polish

Polish  Spanish

Spanish