What stainless steel marking method is best for the food production industry?

Marking & Etching | Friday, 17 June 2022

How to mark metal without compromising food quality

Materials that are in direct contact with food during its production are subject to strict rules and regulations.

So how do you mark and label such materials without compromising food quality?

Read this article and learn about the pros and cons of various metal marking methods and how they affect food quality.

Why is metal marking important in the food production industry?

In many instances, metal parts are marked with declarations documenting their eligibility – to ensure a high standard of production and make the work process easier.

But there can be several other reasons to mark metal parts during food production, and below you can read about a few of them.

Food production machines are often specialized and therefore it is important that they possess vital information – clearly visible to the user.

For instance, it can be beneficial (and often required) to have safety instructions and warnings available to the operators, together with other relevant information such as the date of the last inspection.

With highly specialized equipment, it is essential to have spare parts in stock. If a machine part breaks, marking makes ordering new spare parts easier, thus minimizing production downtime.

How to mark metal parts used in food production?

There are several considerations when marking food production equipment, and not all marking methods can be utilized in this industry.

In the following section, we will have a closer look at the pros and cons of the different metal marking methods used in the food production industry.

Metal embossing

Metal embossing is a method used to emboss the wanted motif onto the metal surface giving it a three-dimensional design whereas the motif is lifted from the surface. This method can also be applied in an opposite manner – called debossing.

Embossing can only be done with fairly simple designs or texts, and thus has some limitations when it comes to the richness of details in the embossed marking.

In general, when marking food production equipment, it is a bad idea to change the structure of the metal surface, because materials can get stuck in the embossed surface and create a hygiene problem.

Laser marking and etching

With laser marking, the metal surface is exposed to focused light beams creating durable markings.

Laser marking can be done with a high level of details in the design, but will leave the surface rough, which may be hard to clean. Another disadvantage is, that laser marking and etching equipment is very expensive, and it’s expensive and time consuming to have the marking done as an outsourced solution.

Dot peen marking

Dot peen(ing) is an engraving process that creates small dots in the metal surface.

In the food production industry, dot peen(ing) can be used for marking date codes and other identifications on products that will be re-packaged later, which can be relevant when a product needs to be tested in a lab before being sold to the customers.

Electrochemical marking

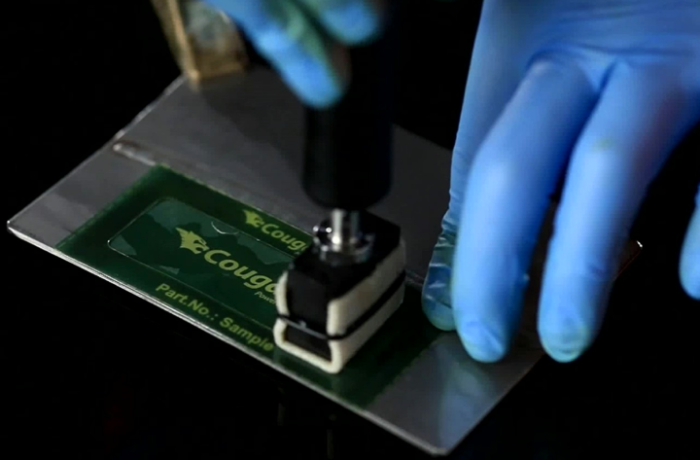

Electrochemical marking is highly applicable in the food production industry. This method is flexible and does not damage the surface. The equipment used is handy, portable, and highly affordable.

The marking is done using a marking head which releases a weak current through a marking template dipped in electrolyte fluid, resulting in a permanent mark on the metal surface.

The marking fluids used for electrochemical marking are mild and do not cause corrosion, making them completely safe for use in food production.

Conclusion

When choosing a suitable marking method for use in food production, there are several important factors to consider. First of all, it is important to know whether the marked metal surface will be in direct contact with food.

If so, then it is important to remember that not all methods are suitable for this type of production – which narrows your choice and provides a useful rule of thumb.

In the food production industry, it is important that the metal surface on the marked subject is not damaged and that the marking does not fade over time.

Electrochemical marking is a proven solution in this industry as it produces clear and durable markings without damaging the metal surface.

If you are in the food production industry and need a flexible marking solution for your production, please don’t hesitate to reach out if you need further information.

English

English  English (US)

English (US)  German

German  Danish

Danish  Swedish

Swedish  French

French  Polish

Polish  Spanish

Spanish