Ask Cougartron Part 9: How well can Cougartron machines clean stainless MIG welds?

Weld cleaning | Ask Cougartron | Tuesday, 25 June 2019

How well can Cougartron machines clean MIG welds?

Welding is a widespread form of metal fabrication covering processes such as TIG, MIG, Stick, and Oxy-Fuel welding.

Thanks to its simplicity and affordability, MIG (Metal Inert Gas) is probably the most common welding method among both industry professionals and hobbyists. The technical name for this process is Gas Metal Arc Welding (GMAW).

Consequently, there is no shortage of questions related to proper cleaning and finishing of welds created using this type of welding.

In the new installment of our Ask Cougartron Q/A series, we respond to one of the more frequent questions: How well can Cougartron machines clean stainless MIG welds?

Before we give the ultimate answer to this important question, we must first go through the basics of MIG welding and reveal some of the key challenges associated with cleaning welds produced using this method.

Main characteristics of MIG welding

MIG welding is a semi-automatic or automatic process in which a consumable wire electrode is fed through the welding gun to the point where the welding takes place and is used as a filler material to help in joining two base metal parts together by forming a weld pool.

Shielding gas is also used to protect the weld pool from contaminants in the air.

Since Cougartron machines are capable of cleaning both MIG and TIG welds, it is beneficial to go through some of the differences between the processes and, in this way, contribute to our final answer.

MIG vs TIG welding – What is the difference?

TIG welding (Tungsten Inert Gas) uses a tungsten electrode and normally a filler material instead of a wire-fed electrode used during MIG welding.

The tungsten electrode has a high resistance to heat and does not melt easily. Similar to MIG welding, an electric arc is formed between the electrode and the workpiece.

This results in melting, but, unlike MIG welding, the electrode remains intact which means that only the base material is affected.

Due to these reasons, TIG welding is more complex and requires greater work precision. It is also much harder to learn and master.

But what are the practical differences between TIG and MIG welds?

Are MIG welds harder to clean and why?

Due to the nature of the process, MIG welds are often susceptible to several different sources of contamination:

- An incompatible filler wire may cause additional oxidation

- Inadequate shielding gas settings can allow contaminants into the weld pool

- Incorrect voltage settings and wire speeds can result in welds that are messier and more oxidized

There is always a way to minimize this through fine-tuning your power settings, and experimenting with different types of electrode wires and shielding gasses.

However, this will work only to a certain degree.

TIG welding is more delicate and thus yields more precise and tidier results. Such welds are much easier to clean and maintain.

There are also a few other factors that must be taken into consideration.

For example, MIG welding is more appropriate when working with thicker metal parts which are naturally harder to clean than thinner steel components and sheet metal.

Thorough surface preparation is also crucial to the success of MIG welding. Namely, the surface must be completely free of all dirt, grease, or corrosive particles before you start fusing the parts. Any remaining residue will cause significant structural and oxidation problems after you finish welding. As a result, your welds will be much harder to clean.

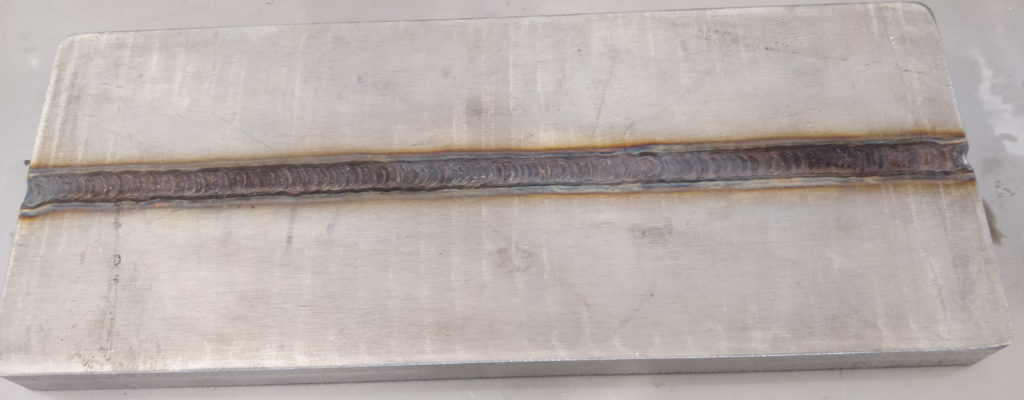

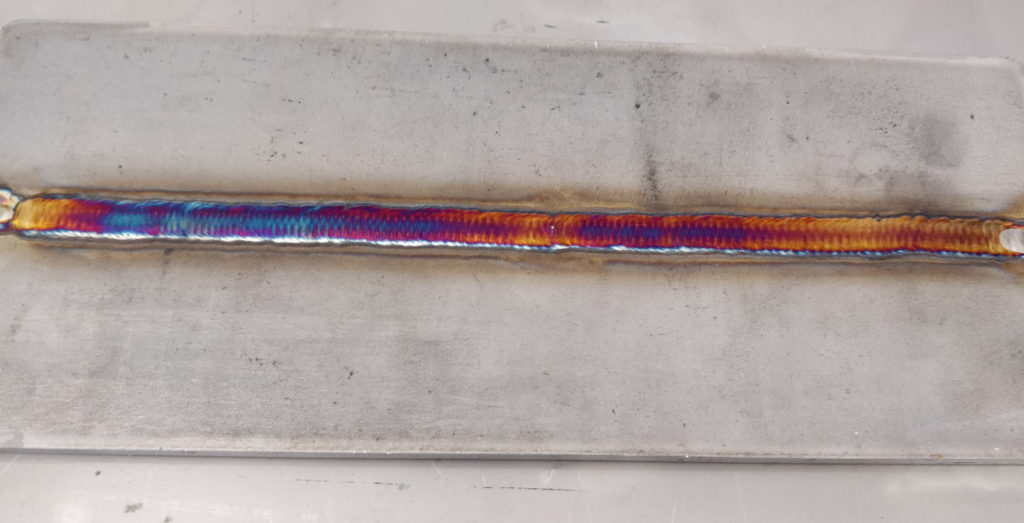

Discoloration is another serious issue affecting both types of welds since the corrosion-resistant layer is destroyed. However, the problem is more pronounced when it comes to MIG welds due to all the aforementioned factors. Usually, darker shades arise as a result of higher welding temperatures and are, consequently, way harder to eliminate during the weld cleaning process.

Click here to read more about removing discoloration from stainless steel welds.

So, how effective are Cougartron machines when solving these issues?

Cougartron equipment for MIG weld cleaning

All Cougartron machines are capable of cleaning light and dark stainless steel TIG welds. We can safely argue that this form of weld cleaning is almost no challenge for our equipment.

However, as we established earlier,

MIG welds are much more difficult to clean. Due to this fact, only our high-powered machine models can cope with heavy oxidation and other forms of contamination usually appearing after MIG welding.

Lighter MIG welds (up to 5mm or 3/16 inch) can be successfully cleaned using either Cougartron ProPlus.

Larger, darker and highly-discolored MIG welds, created using the wrong shielding gas or filler wire, can only be treated with the help of Cougartron FURY models FURY 100 or FURY 200.

FURY weld cleaners are very powerful, thus have the ability to remove all traces of rust, residue, and discoloration appearing on welds after all types of welding. FURY will also re(passivate) the surface and prevent some of the usual problems with corrosion appearing within crevices and pores created during MIG welding.

Thanks to its strength, FURY can use up to three brushes at the same time which makes it extra efficient when cleaning larger welds and surfaces.

To answer our initial question – Cougartron machines can clean stainless MIG welds remarkably well. However, you have to make sure to pick the right machine for the job.

Need help with MIG weld cleaning?

Loading...

Please wait while the form loads.

Best Equipment for MIG Weld Cleaning

Loading products...

Please wait while the products load.

English

English  English (US)

English (US)  German

German  Danish

Danish  Swedish

Swedish  French

French  Polish

Polish  Spanish

Spanish